Stone mills have a long history and have been used in various cultures around the world for centuries. They were commonly used in agriculture to process grains into flour or meal, but they were also used for other purposes like grinding spices, making oils, or milling other materials. Stone mills were traditionally powered by human or animal labor, such as through manual rotation or the use of water or wind power.

what is Stone Mill?

A stone mill is a type of machinery used to process grains such as rice, wheat, beans, etc., into powder or paste. It was initially operated by human or animal power. During the Jin Dynasty, the Chinese people invented water mills that utilized water as the driving force. A stone mill typically consists of two circular stones. The grinding surfaces of the two stones have textures, and the grains enter the space between the two layers through an opening. As the stones roll, the grains are crushed along the textures, resulting in the formation of powder.

what are Chinese stone mill called?

In China, a grist mill is known as a “磨坊” (mó fāng) or “磨石” (mó shí). A grist mill is a mill that grinds grains into flour or meal. It typically consists of a pair of grinding stones, with the lower stone being stationary and the upper stone rotating. The grains are fed into the gap between the stones, and as the upper stone rotates, it crushes the grains against the lower stone, resulting in the production of flour or meal.

A stone mill, originally called “Wei” and later referred to as “Mo” during the Han Dynasty, is the most primitive type of flour processing machinery. It consists of a grinding table and a grinding disc. Stone mills were operated using human power, animal power, or water power. Water-powered stone mills were invented around the Jin Dynasty. The power component of a water mill is a horizontal water wheel, with the upper fan of the mill installed on a vertical axis. Flowing water drives the water wheel, which in turn rotates the mill. This type of mill is suitable for installation in locations where there is a strong water current. If the water current is relatively weak but there is a large volume of water, another form of water mill can be installed: the power mechanism is a vertical wheel with a gear mounted on the wheel shaft, which meshes with a gear mounted on the lower part of the mill shaft. The rotation of the water wheel is transmitted to the mill through the gears. Both forms of water mills have a simple structure and wide application.

what is Chinese stone mill look like?

A stone mill consists of several components, including the mill base, millstone, lower fan, upper fan, and mill handle. The mill base serves as the foundation of the stone mill and is typically constructed using three stable stones. The size and height of the base depend on the dimensions of the stone mill. The millstone is a large stone that is carved into a flat circular shape, with a diameter of about 90 centimeters and a thickness of approximately 12 centimeters. It features a circular groove around the perimeter, about 10 centimeters wide and 5 centimeters deep, with a protruding spout used to collect and dispense the ground soybean milk or rice flour. The lower fan is a circular stone that sits on the millstone, with a diameter of around 60 centimeters and a thickness of approximately 15 centimeters. It has a square hole at the center, which accommodates a cast iron mill hub, usually square on the bottom and circular on the top, with a diameter of about 5 centimeters. Alternatively, a metal ring can be used as a mill hub, encased in a hard wooden exterior. The lower fan serves as the axis of the stone mill, connecting to the upper fan and facilitating its smooth rotation. The upper fan has the same diameter and thickness as the lower fan, with a circular mortise at the bottom center, where an iron ring is fitted. The inner diameter of the ring matches the mill hub of the lower fan. On either side of the upper fan, there are two corresponding round holes, approximately 5 centimeters in diameter, into which wooden rods, about 15 centimeters long, called mill handles, are inserted. These handles are used to secure the mill handle or lift the mill fans. Near the central point, one or two transparent mill holes, about 7 centimeters in diameter, are carved to allow for the feeding of grains and the addition of water. Both the lower and upper fans have distinct tooth marks, with the width, depth, and spacing of the tooth marks determined by the mill’s specifications. The tooth marks exhibit a diagonal radial pattern. The central point of the upper fan is deeply carved, gradually becoming shallower toward the edges, forming an arc that disperses outward. This central area where the upper and lower fans combine is commonly referred to as the mill cavity. Another component is a rectangular iron ring called the mill pull, which is hung on the mill handle. As the mill fans rotate, the mill pull travels along the grooves on the edge of the millstone, pulling the ground soybean milk or rice flour towards the mill outlet and into a receiving container. The slightly curved mill handle is attached to the mill handle, and grains to be processed are placed in the mill hole. By pushing or pulling the upper fan of the stone mill, it can be operated and processed.

Unlike a rolling mill, a stone mill cannot be easily moved when empty due to the strong adhesion between the tooth marks of the upper and lower fans. It requires significant force to start the mill. However, once grains are added, they disperse outward in the mill cavity, gradually forming grain powder that lubricates the space between the upper and lower fans. This makes it much easier to push the stone mill. Mischievous children are therefore unable to play with the stone mill.

There is also a common small stone mill, approximately 25 centimeters tall and 35 centimeters in diameter, weighing about 50 kilograms. It consists of two parts, the upper fan and the lower fan, with the lower fan integrated into the millstone. The principle of operation for the small stone mill is the same as that of the larger stone mill. However, it is smaller in size, lacks a mill base, does not require a mill handle or mill pull, and only features a handle attached to the upper fan for single-arm rocking. These small stone mills are typically used indoors by homeowners. They are lightweight, flexible, and suitable for processing small quantities of food, similar to modern soybean milk machines.

style of Chinese stone mill

Stone Mill:

A stone mill is an ancient mechanical device used in rural China to process grains such as rice, wheat, and beans into flour or paste. It is made of sandstone and consists of two circular grinding stones, typically with diameters ranging from 50 to 120 centimeters. One stone serves as the base while the other is placed on top and can rotate. The central part of the base stone has a hole where an iron axle is fixed, and the top stone has a hole with an iron ring that fits onto the axle. The grinding process involves feeding the grains through holes in the top stone, and as the top stone rotates, the grains are ground and pushed outward along the textured surfaces, eventually flowing out through the gap between the two grinding stones.

During the Jin Dynasty, the invention of the water mill introduced the use of water as a source of power to drive the stone mill. The water mill typically features a horizontal water wheel mounted on a vertical shaft, with the upper grinding stone attached to the wheel. The flow of water drives the wheel, which in turn rotates the grinding stones. This type of mill is suitable for locations with a strong water current. Alternatively, if the water current is weaker but abundant, another form of water mill can be used. This type has a vertical wheel with gears on its shaft that mesh with gears mounted on the lower part of the grinding stone. The rotation of the water wheel is transmitted to the grinding stone through the gears. Both types of water mills have simple constructions and wide applications.

Stone Mill for Grinding Tofu:

The stone mill for grinding tofu is a specific type of stone mill used in the past to process soybeans into tofu. Its principle of operation is similar to that of grinding wheat or corn with a stone mill. However, it is smaller in size, with a diameter of approximately 40 centimeters. The top stone is concave, and the base has raised edges. This design is meant to accommodate the grinding of soybeans into a paste-like consistency, which requires the addition of water to prevent it from flowing away.

Stone Mill for Millet and Millet Flour(Shi Nian):

The stone mill for millet and millet flour is another type of stone mill used for processing millet flour and millet in rural areas before the 1980s. It is similar to a regular stone mill but specifically used for millet flour processing. The main components of this mill are the grinding disc base, which features a fixed wooden or iron pillar in the center, and the grinding stone. The grinding stone has a diameter of approximately 100 centimeters and has two holes at each end where iron mortars are embedded. A metal frame is fixed to the stone, with two tapered iron axles at the middle of each side. These axles rotate within the iron mortars, allowing the grinding stone to move in a circular motion on the grinding disc. By pushing or pulling a long wooden rod attached to the metal frame, the grinding stone can be rotated, resulting in the crushing of millet into flour or the removal of husks to produce millet grains.

The use of a stone mill for millet processing is specifically chosen to achieve a fine and smooth texture in millet flour, which is desirable for making a local delicacy known as “bu fan mo.” Millet flour processed using a stone mill produces a particularly good texture for this dish, while millet flour processed using a regular stone mill may not yield the same desired texture.

A stone millstone, also known as a “niǎn” in Chinese, is a tool made of stones and wood used for crushing or husking grains. It consists of a grinding disc (stone platform), a grinding pestle (stone roller), a grinding frame, a grinding tube core, grinding pestle holes, and grinding pestles.

The stone millstone is divided into two parts: the upper part is called the grinding pestle, and the lower part is called the grinding disc. The contact surface between the grinding disc and the grinding pestle has neatly arranged grinding teeth, with the middle ones deeper than the ones on the sides. The grinding pestle has neatly arranged grinding teeth, with one side deeper than the other. These teeth are used to grind the grains. The grinding pestle is fixed on the grinding frame (with the deeper side of the grinding teeth in the middle), and the grinding frame is a quadrangular frame made of hardwood (usually jujube wood). The grinding pestle has two small concave pits in the center, in which a small iron bowl called the grinding navel is fixed. Correspondingly, two round iron rods are fixed on the grinding frame, opposite to the grinding navel, fitting together and able to rotate freely. One end of the grinding frame has a hole that fits onto the grinding tube core, which is a metal cylinder fixed in the center of the grinding disc. The grinding frame usually has two grinding pestle holes as well.

Once all the components are ready, the grinding pestles are attached, and the stone millstone is ready to use. The grinding pestles are two wooden sticks, each about one meter long, inserted into the two grinding pestle holes diagonally. When the grinding pestles are pushed counterclockwise, the grinding pestle starts to rotate, and the stone millstone begins its work.

After using it for a period of time, the grinding teeth become worn down and need to be re-engraved by a stonemason to give this stone tool a new lease of life.

Stone Mortar for Pounding Rice:

The stone mortar for pounding rice is an ancient tool used by the Li ethnic minority in China to process rice. The earliest form of this tool was simple and consisted of a stone mortar (made of limestone or sandstone) and a wooden pestle. People would manually pound the rice in the stone mortar, removing the husks from the rice grains.

Later, a more efficient device was invented to reduce labor. It consisted of a wooden pestle attached to a long handle, with the handle fixed to a wooden frame near the stone mortar. By stepping on the handle, the wooden pestle could move up and down, pounding the rice in the stone mortar.

Although this improved version reduced effort and increased efficiency compared to manual pounding, it still required significant physical exertion. Pounding a mortar full of rice would typically require around 300 strokes and take about an hour. In the Li ethnic community, women were primarily responsible for this task.

Modern Stone Mills:

Modern stone mills retain the grinding mechanism of traditional stone mills, which consists of two cylindrical stones. However, the traditional power generation devices have been replaced by electric motors, resulting in improved efficiency and reduced labor. Additionally, modern stone mills are equipped with conveying and cleaning devices.

The conveying device includes a large hopper, a fan, a wind shifter, a shaking sieve, and pipelines. The cleaning device includes a screen cloth, brushes, and a circular sieve. Modern roller stone mills combine the traditional low-speed grinding process with advanced design features such as automatic circulation. They are equipped with screening and powder collection devices, allowing for fully automated operations while preserving the traditional characteristics of stone milling, such as precise grinding and fine milling. The introduction of modern roller stone mills has greatly increased production efficiency while reducing labor requirements.

Modern roller stone mills consist of major components such as a large hopper, a fan, a circular sieve, a wind shifter, a shaking sieve, rock grinding rollers, and pipelines.

what are the Chinese stone mill made of?

Chinese stone mills are typically made of sandstone or other types of natural stone. The specific type of stone used can vary depending on the region and availability of suitable materials. Sandstone is commonly used due to its durability, hardness, and ability to hold a sharp cutting edge. It is also resistant to wear and provides good grinding performance. Other types of stone that have been historically used for Chinese stone mills include limestone and granite, although sandstone remains the most common choice. The stones are carefully selected for their quality and suitability for grinding grains and other materials.

what are the Chinese stone mill used for?

Chinese stone mills are machines used for processing grains such as rice, wheat, and beans into flour or paste. They were initially operated manually or by animal power. In the Jin Dynasty, water-powered stone mills were invented in China. Typically, a Chinese stone mill consists of two circular stones. The grinding surfaces of the stones have textures, and grains enter the space between the two layers through a hole on the top stone. As the stones rotate, the grains are ground and crushed along the textures, resulting in the formation of powder.

One important function of the stone mill is grinding soybeans for tofu production. Due to the requirement for convenient access to water sources and addressing freezing issues during winter, stone mills were often placed in millhouses, which offered better conditions compared to other grinding devices. When making dried tofu, the stone mill needed suitable water sources and controlled temperatures to ensure the production of high-quality dried tofu. Shared stone mills were typically placed near windows in the main building because the temperature in front of the windows would be several degrees higher than in other outdoor areas during winter. If the temperature dropped too low or unexpected freezing occurred, a common solution was to heat water in large iron pots and pour it over the stone mill.

For traditional stone mills that are no longer in use, there are various ways to repurpose them and make use of their residual heat. Some of the methods include:

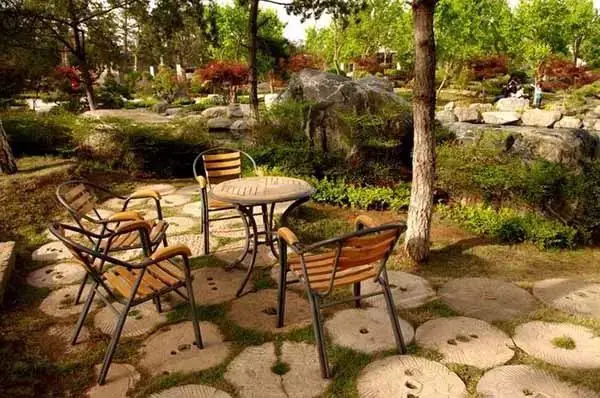

Road paving: When a large number of stone mills are available, they can be used as pavement material. The circular grinding stones can be laid flat on the ground, and the circular shape allows for flexible combinations. The gaps between the stones can be filled with stones or grass, enhancing the rural characteristics of the roads.

Retaining walls: Stone mills can be used to construct retaining walls in areas with minor topography or around tree pits. In addition to conventional methods using stone slabs, reinforced concrete, etc., stone mills themselves are made of stone and possess a certain load-bearing capacity, meeting the requirements of retaining walls.

Streamside footpaths: Stone mills can replace traditional footpaths in shallow water streams, enriching the rural water landscapes.

Small bridges: Stone mills can serve as road connections over narrow water surfaces.

Landscape features: Stone mills can be restored to their original usage scenes as landscape features in idle spaces, emphasizing rural nostalgia. They can also be creatively used, such as dividing spaces as walls, combining with other materials for innovative landscaping, or incorporating water elements as water features.

Characteristic tables and chairs: By combining stone mills of various sizes with other commonly found materials in rural areas, large grinding stones can be used as tables and smaller ones as stools. The materials have a simple and rustic aesthetic, fitting the rural living scene.

Steps: Uniformly processed stone mills of the same size can be used as steps, providing safe and aesthetically pleasing connections between terraces.

With a considerable number of idle stone mills in rural areas, utilizing them on-site offers cost savings, reuses old materials, and reduces material waste. Stone mills are a special material that should not be overlooked in rural design, and their usage has evolved over time.

how does a stone mill work?

A stone tool used to husk or grind grains into powder or flour using human or animal power. It consists of two similarly sized short cylindrical stones and a grinding disc. Typically, it is placed on a platform made of stone or clay bricks, with the grinding disc, made of stone or wood, stacked with the stationary lower disc and the rotating upper disc. Both discs have neatly arranged grinding teeth on their contact surfaces to crush the grains. The upper disc has two (or one for smaller mills) grinding openings for the grains to pass through. A spindle (iron axle) is placed between the two discs to prevent the upper disc from falling off the lower disc while rotating. Large mills with a diameter exceeding 1.2 meters require three horses to pull, and it takes just over ten minutes to grind one dou (about 50 kilograms) of grains. Generally, mills with a diameter of around 80 centimeters can be operated by one person or a donkey. Smaller mills with a diameter less than 40 centimeters can fit in a basket and be hand-operated, commonly used for grinding pepper powder, among other purposes. There are also water mills used for extracting tofu juice and making pancake batter.

A Chinese stone mill is composed of several components, including the mill base, grinding disc, lower fan, upper fan, and grinding rod. The mill base serves as the foundation of the stone mill and is typically constructed using three stable stones, with the size and height determined by the dimensions of the stone mill. The grinding disc is a large stone that is chiseled into a flat circular shape, measuring approximately 90 centimeters in diameter and 12 centimeters thick. It features a circular groove around the perimeter, about 10 centimeters wide and 5 centimeters deep, with a protruding spout used to collect and dispense the ground soy milk or rice flour.

The lower fan is a circular stone placed on top of the grinding disc, with a diameter of approximately 60 centimeters and a thickness of about 15 centimeters. It has a square hole at the center that accommodates a cast iron mill navel, which is square at the bottom and round on top, with a diameter of around 5 centimeters. Alternatively, a metal ring can be used as the mill navel, encased in a hard wooden structure. The lower fan serves as the central axis of the stone mill, connecting to the upper fan and enabling smooth rotation.

The upper fan has the same diameter and thickness as the lower fan, with a circular mortise hole at the bottom center fitted with a metal ring matching the mill navel of the lower fan. Two corresponding round holes, approximately 5 centimeters in diameter, are chiseled on each side to insert wooden pegs, called grinding handles, which are used to secure the grinding rod or lift the grinding fans. Adjacent to the central point, one or two transparent grinding eyes with a diameter of approximately 7 centimeters are chiseled to allow for feeding and adding water. Both the lower and upper fans are carved with distinct and textured teeth marks, whose width, depth, and spacing depend on the grinding pattern. The textures are arranged in diagonal radiating lines. The center point of the upper fan is carved deeper and gradually becomes shallower towards the edges, forming an arc-shaped pattern that disperses outward. This central part where the upper and lower fans combine is commonly referred to as the grinding chamber.

There is also a rectangular iron ring called the grinding puller, which is hung on the grinding handle. As the grinding fans rotate, the puller moves along the grooves at the edge of the grinding disc, pulling the ground soy milk or rice flour towards the outlet of the grinding disc and into a receiving container. The slightly arched grinding rod is tied to the grinding handle, and the processed grains are placed in the grinding eyes. By pushing or pulling the upper fan of the stone mill, the operation and processing can commence.

Chinese stone mill history

The grinding device, initially called “wei” and later known as “mo” during the Han Dynasty, has undergone three developmental periods in China: early, middle, and late.

The early period, ranging from the Warring States period to the Western Han Dynasty, was characterized by concave pits as the main type of grinding teeth. The pits had various shapes, including rectangular, circular, triangular, and jujube seed-shaped, and were highly irregular and diverse.

The middle period, from the Eastern Han Dynasty to the Three Kingdoms period, witnessed a diversified development of grinding teeth. The tooth shapes were divided into radial zones and diagonal lines, such as the four-zone, six-zone, and eight-zone patterns.

The late period, from the Western Jin Dynasty to the Sui and Tang Dynasties (until today), marked the mature stage of stone mill development. The mainstream grinding teeth during this period were the eight-zone diagonal line pattern, with some variations featuring ten-zone diagonal lines.

Grinding devices were operated using human power, animal power, or hydraulic power. Water-powered grinding mills were invented around the Jin Dynasty. The power component of a water mill was a horizontal water wheel, with the upper fan of the mill mounted on the vertical axis of the wheel. The flowing water impelled the water wheel, which in turn rotated the mill. This type of mill was suitable for installation in places with strong water flow. If the water flow was relatively weak but abundant, another form of water mill was employed. The power mechanism consisted of a vertical wheel with a gear mounted on its axle, which meshed with a gear fixed horizontally on the lower part of the mill shaft. The rotation of the water wheel was transmitted to the grinding process through the gears. These two forms of water mills had simple structures and widespread applications.

As history progressed to the 1970s, people ingeniously combined ancient techniques with modern elements, creating stone mills driven by electric motors. Two styles of electric stone mills emerged, including the disc-type stone mill and the roller-type stone mill. The grinding part of the disc-type stone mill was divided into fixed and rotating sections, forming a horizontal structure. The fixed part featured a half-cylindrical groove on one long side of a rectangular stone, matching the rotating section. The rotating section was made into a cylindrical shape, with a hole in the middle for the drive shaft. The contact surface between the semi-circular stone groove and the rotating cylinder was engraved with patterns similar to those found on ancient stone mills. Additional covering was applied to conceal the transmission components, resulting in a combination of ancient and modern elements. The grinding part of the roller-type stone mill consisted of cylindrical rock rollers, resembling the grinding rolls of steel mills. The surface of the rollers was engraved with patterns similar to those found on ancient stone mills.

who invented Chinese stone mill?

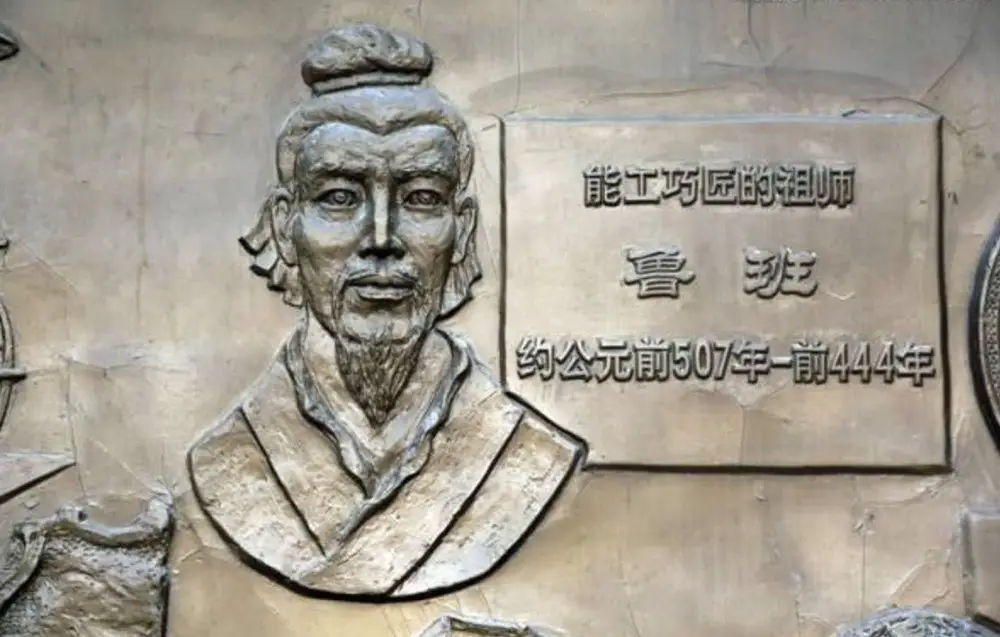

Lu Ban was an outstanding ancient Chinese inventor and creator. He lived during the late Spring and Autumn period and was originally named Gongshu Ban. However, because he hailed from the state of Lu, he became known as Lu Ban. It is said that he invented various woodworking tools such as saws, planes, and compasses. With his intelligence, he also solved many problems in people’s daily lives.

During Lu Ban’s time, people used stone mortars and coarse stone pestles to grind rice and wheat into flour. This method was laborious, resulting in both coarse and fine flour, and only a small amount could be ground at a time. Lu Ban sought to find a more efficient way to achieve greater results with less effort. He created grinding fans using two flat cylindrical stones of a certain thickness. The lower fan had a short vertical axle made of iron, while the upper fan had a corresponding hollow sleeve. When the two fans were combined, the lower fan remained fixed while the upper fan could rotate around the axle. On the facing sides of the two fans, there was an empty chamber called the grinding chamber, which was surrounded by interlocking grinding teeth. The upper fan had grinding eyes, allowing grains to enter the grinding chamber during the grinding process. The grains were evenly distributed around the chamber and ground into powder. The powder would flow onto the grinding pan through the gaps and be sifted to obtain flour, free from bran and other impurities.

Even today, many rural areas still use stone mills for grinding flour.

when invented Chinese stone mill?

The emergence of stone mills coincided with the widespread cultivation of crops. In the ancient period, around seven to eight thousand years ago, the ancestors of the Chinese nation adapted to their environment and cultivated millet in the Yellow River Basin and rice in the Yangtze River Basin. This primitive form of agriculture greatly improved and enhanced human dietary levels, leading to the invention of the oldest grain processing tools, stone millstones, and stone pestles. However, during this time, the stone millstones and pestles were not the circular stone mills we refer to today. The ancient stone millstones and pestles had surfaces that were mostly elongated or oval-shaped, resembling long strips or willow leaves. They were relatively large in size. The method of use involved placing grains on the stone millstone and continuously kneading and rubbing them with the elongated stone pestle to remove the outer husk. Some millstones had flat bottoms, while others had raised feet. The purpose of having feet beneath the millstone was to facilitate the storage of processed grains that inevitably scattered near the millstone during the grinding process. Moreover, the millstones were typically not placed directly on the ground but on other objects, such as being placed inside winnowing baskets, to prevent the grains from falling onto the ground. However, placing the millstone inside a winnowing basket made it prone to sliding. The invention of millstones with feet may have been related to preventing the millstone from sliding. Alongside the emergence of millstones, another widely used tool was the simple grain processing tool known as stone pestles and wooden mortars. Stone pestles were cylindrical stones used to pound grains, remove husks, or grind flour. Later on, due to the difficulty of shaping stones into pestles, wooden mortars became widely utilized. The “Book of Documents,” which is said to have been compiled by historians in the pre-Qin period (or some say the Han Dynasty), records the genealogies, surnames, titles, and capitals of emperors, nobles, and officials from the Yellow Emperor to the Spring and Autumn Period. In this book, it is mentioned that “Gongshu Ban made the ‘wei'”—and “Gongshu Ban” refers to Lu Ban. Lu Ban (507 BCE–444 BCE) was a skilled craftsman from the State of Lu during the late Spring and Autumn period and the early Warring States period. He was from the Gongshu clan, with the given name Ban and the courtesy name Yizhi. He was also referred to as “Gongshu Zi” and “Lu Pan” or “Lu Ban.” It is commonly known as “Lu Ban.” The term “wei” in the text refers to a circular stone mill. Therefore, it can be inferred that circular stone mills had already appeared during the late Spring and Autumn period and the early Warring States period.

where Chinese stone mill originated?

In 1968, in the Han tomb in Mancheng, Baoding City, Hebei Province, a stone mill dating back approximately 2,100 years was unearthed. It was a composite mill made of stone and copper, consisting of a stone mill and a copper funnel. This is the earliest discovered physical evidence of a stone mill in China to date.

what does Chinese stone mill symbolize?

The stone mill is not only an agricultural tool but also holds deep cultural significance, serving as a widely recognized symbol with diverse symbolic meanings.

The close connection between the mill and grain production links it closely to prosperity and wealth. In rural areas, the stone mill holds a revered position akin to a granary. In the past, it was considered a remarkable achievement for a household to acquire a stone mill. If a stone mill was included as part of a dowry or bride price, it became a source of pride and boasting.

The symbolism of the stone mill conveys the message of “perseverance through hardships,” encouraging people to withstand the trials of life. It also represents the concept of “turning fortunes,” emphasizing the importance of persistence after facing setbacks. In rural areas, there are certain beliefs associated with the stone mill. According to the principles of Yin and Yang and the Five Elements, the stone mill represents the “White Tiger” and is revered in the “Western” direction.

Due to its close association with abundance, the stone mill holds a prevalent symbolic significance as a representation of fertility worship, becoming a distinctive symbol of fertility worship. This symbolism can be traced back to ancient myths such as the story of Fu Xi and Nü Wa, siblings who married and created humanity. The mythological account, as described by Tang Dynasty scholar Li Rong in the “Duyi Zhi,” introduced the element of “rolling the stone mill.” According to Chen Jun’s “New Discourse on Chinese Mythology,” in the 1980s, researcher Cheng Jianjun and the Central Plains Mythology Investigation Team collected several myths from the Tongbai Mountain area in the Yellow River Basin, including “Pangu’s Birth” and “Jiulong Mountain.” In these myths, Fu Xi transformed into Pangu. Here is a brief description:

According to the legend, after Pangu created the heavens and the earth and formed the Tongbai Mountain, he rested there. Later, floods engulfed the world, and humanity faced destruction. Pangu and Nü Wa were saved by stone lions, allowing them to survive. After the siblings repaired the holes in the sky, they rolled a stone mill together and became husband and wife, thus bringing human life into the world.

The motif of Pangu and Nü Wa rolling a stone mill during their marriage shares striking similarities with the myth of Fu Xi and Nü Wa, particularly the act of rolling the stone mill, which serves as a profound interpretation of the symbolic significance of the mill.

The reverence for the mill is evident in the taboos associated with it. In rural areas, it is considered highly inauspicious to build a house on a burial ground or a mill path. The common belief is that the mill path represents the “White Tiger,” and if a house is constructed in such a location, it is believed to bring misfortune and death to the occupants. While the taboo associated with burial grounds is relatively understandable and holds deep cultural significance, the taboo related to the mill path is more challenging to comprehend. According to the viewpoint of cultural anthropology, the taboo surrounding a particular object stems from the belief in its significant power. The primary reason behind this belief is rooted in reverence and worship. Similarly, people’s psychology towards the mill resembles this pattern. People firmly believe that the mill possesses both blessing and calamity, expressing their reverence and numerous taboos. The contradictory psychological attitudes towards the mill indicate its significant importance in people’s minds. Overall, people believe that the mill has a soul, possesses immense power, and is considered sacred.

The tremendous power attributed to the mill creates a sense of mystery surrounding the millhouse, making it a symbol of sanctity. In many surreal literary and cinematic works, similar representations can be found. Scenes set in the millhouse are often characterized by an atmosphere of gloom and mystery: dimly lit millhouses with elusive figures give rise to a sense of unease. The tense and suspenseful background music keeps the viewers on edge, and suddenly, inexplicable disasters occur. Unearthing the profound meaning behind such visuals can still be traced back to the awe and worship of the stone mill. Furthermore, it demonstrates that the symbolic significance of the mill has evolved beyond mere folk cultural beliefs and has permeated artistic creations, exerting a widespread influence. Renowned German children’s author Otfried Preußler even wrote a work titled “The Ghost Mill,” describing the journey of a shepherd’s son who studies, grows, and battles at the mysterious magical school called the “Ghost Mill.” This highlights the significant role of the millhouse. The mill in such magical works possesses the power of an archetype and influence.

Furthermore, the constant rotation of the mill is often used as a symbol of cosmic and worldly cycles, as well as dangerous whirlpools. The repetitive labor of grinding with the mill is synonymous with arduous toil. These themes can be found in Homer’s epic “The Odyssey,” the legends of the mighty Samson in the Bible, and various works in Chinese literature, including “Mencius.” The vertical axis in the center of the mill also symbolizes a pillar, which is documented in legends from Japan, Central America, the Maori people of New Zealand, and the oldest North Indian literary work, the “Rigveda.” Scholars Suchandra Ghosh and Dai Chengde, in their work “Hamlet’s Mill,” synthesized myths from different cultures, regarding the mill as a symbol of the cosmic mechanism, believing it conveys “precessional information.” In conclusion, the stone mill carries rich cultural connotations, opening the gateway to human inspiration and encompassing a multitude of interpretations in human culture, adding vibrant hues to its tapestry.

Chinese stone mill in Yin and Yang

The stone mill consists of two grinding wheels with carved teeth. Yin and yang are the cornerstone of Chinese culture. It can be speculated that the original designer of the stone mill based its design on the concept of yin and yang, forming the two wheels of the stone mill, one resembling the sun and the other resembling the moon, or one resembling a man and the other resembling a woman. Typically, the largest diameter can reach 1.1 meters, weighing around 300 kilograms, with a grand and peculiar appearance. The smallest diameter is only about 10 centimeters, small enough to be held in the palm of one’s hand. They come from different places, made of different types of stones, and have different ages. Some have a history of several hundred years, while others may only be a few decades old. The size of the stone mill can indicate its purpose, with larger ones used for grinding food, medium-sized ones used for grinding herbs, and smaller ones used for kneading tea. Some stone mills have various patterns, including figures, carvings, animals, and text. Some stone mills, based on the patterns of the stone, have beautifully crafted lotus flowers when the upper and lower parts are combined, making them exquisite works of art. These patterns can also provide insights into the aesthetic taste and level of affluence of the owners of the stone mills at that time.

The diameter of the grinding wheel is about 80 centimeters, and the thickness of a single wheel is about 20 to 30 centimeters. The upper wheel is slightly thicker than the lower wheel to exert pressure on the grains. The upper wheel has a central hole through which a wooden or iron rod, called the “mill spindle” or axis, is inserted. The lower wheel has a central hole at its center, and an iron sleeve called the “mill navel eye” is placed in it. This sleeve fits onto the mill navel in the middle of the lower wheel to prevent the upper wheel from falling off when it rotates. When the upper and lower wheels are closed together, they represent the union of yin and yang, bringing heaven and earth into harmony.

The junction of the two wheels has interlocking, symmetrical, uneven, and orderly grooves called “mill teeth.” The lower edge of the upper wheel within ten centimeters is chiseled with a shallow depression below the plane, called the “mill chamber,” used to pile up grains and prevent them from flowing out.

The top of the upper wheel is carved with two fist-sized round holes, very symmetrical, resembling human eyes, called the “mill eyes.” The edges are evenly carved with three circular stone eyes connected to the sides, used to attach ropes for pulling the grinding lever.

Chinese stone mill in Fengshui

In ancient Feng Shui, regardless of the past or the future, the stone mill still holds a place and plays its role in Feng Shui. The stone mill is a Feng Shui tool, and I will briefly explain its role and characteristics in Feng Shui:

Characteristics of the stone mill:

- Large and grand in shape.

- The distribution of grooves on the grinding wheel forms a rotating hexagram pattern.

- The number of grooves in the hexagram pattern is arranged with both odd and even numbers, representing the distribution of yin and yang and corresponding to the Tai Chi.

- The flow holes in the rotating disc of the stone mill bear a striking resemblance to the concept of black holes mentioned by modern scientists.

- Represents the most primitive hexagram patterns.

Functions of the stone mill:

- Serves as a remedy against negative energy (represented by the White Tiger).

- Acts as a protective charm against evil spirits.

- Reverses the magnetic field.

- Promotes harmony and unity.

- Assists in pursuing and capturing fleeing energies.

Stone Mill and Tofu

Stone mill tofu refers to tofu made by grinding soaked soybeans into soy milk using a stone mill, and then heating the soy milk to solidify it into tofu. Compared to regular tofu, it has a richer soy aroma and texture, making it a traditional delicacy.

The process of making stone mill tofu is relatively intricate and involves multiple steps. First, dry soybeans are soaked in water, and then they are slowly ground into fine soy milk using a stone mill. When grinding the soy milk, attention should be paid to the temperature of the stone mill and the quality of the stones. The better the quality of the stones, the finer the soy milk obtained. Next, the soy milk is filtered to remove impurities and then heated to around 80 degrees Celsius. After stirring evenly, some salt is added for seasoning.

The process of making stone mill tofu may seem simple, but it requires attention to detail. For example, adding a certain amount of starch and vinegar to the soy milk can adjust the texture. It is also important to control the appropriate cooking temperature during the tofu solidification process to ensure the desired texture and nutritional content.

As a traditional delicacy, stone mill tofu not only has a delicious taste but also carries rich cultural connotations. It is not only a characteristic cuisine of the Dianchi Lake area but also an essential part of the local rural traditional culture.

In the Dianchi Lake area, stone mill tofu has always been a daily staple for the local people and can be served from breakfast to lunch. Different cooking methods and flavors add colorful variations to this dish. Along the development process, stone mill tofu has also become a cultural heritage of the region, gaining popularity and love from an increasing number of people.

In addition to its cultural and culinary values, stone mill tofu also has various medicinal benefits. Research has found that stone mill tofu is rich in protein, amino acids, and vitamins, which have positive effects on enhancing physical health and promoting digestion.

In summary, stone mill tofu is not only a traditional culinary delight and a reflection of folk culture but also a representative of healthy food. While its production process may be intricate and require skill, the unique soy aroma and texture experienced when tasting well-made stone mill tofu evoke a sense of tradition and emotion.

stone mill and donkey

Stone mill and donkey have a historical connection in certain cultural contexts, particularly in traditional agricultural practices. In some rural areas, a donkey is used to power or operate a stone mill.

A stone mill is a device used for grinding or milling various substances, such as grains, spices, or seeds. It consists of two rotating stones, with the top stone being turned by an external force, often provided by a donkey walking in a circular path. The bottom stone remains stationary, while the top stone grinds or crushes the material between them. The use of a donkey as a source of power for the stone mill is a traditional method that has been employed for centuries.

The donkey’s circular movement is harnessed to drive the stone mill, providing the necessary rotational force to grind the substances. This symbiotic relationship between the stone mill and donkey demonstrates the ingenuity of utilizing animal power to perform manual labor tasks in agricultural settings.

It’s worth noting that the use of a donkey to power a stone mill is just one example of animal-powered milling methods. Throughout history, various animals, such as horses, oxen, or even humans, have been employed to power mills and other machinery.

The combination of a stone mill and a donkey represents a traditional and efficient approach to processing agricultural products, providing a practical solution for grinding grains or other materials in areas where electricity or modern machinery may be scarce. This practice has historical and cultural significance, showcasing the resourcefulness and adaptation of communities to meet their basic needs using available resources.

Chinese stone mill VS Mortar

Chinese Stone Mill:

The Chinese stone mill, also known as a quern mill or grinding mill, is a traditional tool used for grinding grains, seeds, and other materials. It consists of two large round stones, typically made of granite or basalt, with one stone placed on top of the other. The top stone is rotated manually or by an animal or machinery to grind the material placed between the stones. The grinding action is achieved through the friction and crushing of the grains between the stones, resulting in the desired texture or fineness of the ground product.

Mortar:

A mortar is a bowl-shaped vessel made of various materials such as stone, ceramic, or metal. It is used for grinding, crushing, and mixing substances, particularly in food preparation and pharmaceutical applications. The mortar is paired with a pestle, which is a handheld tool with a rounded end used for pounding and grinding within the mortar. The pestle is moved in a circular motion, pressing and grinding the ingredients against the mortar’s inner surface to break them down and create a paste or powder.

While both the Chinese stone mill and mortar serve similar purposes of grinding and crushing, there are some key differences between them. The Chinese stone mill is typically larger and heavier, designed for grinding larger quantities of grains and seeds. It operates by rotating the top stone over the stationary bottom stone. On the other hand, a mortar is usually smaller and more portable, suitable for grinding smaller amounts of ingredients. The pestle is used to manually crush and grind the materials against the mortar’s interior surface.

Both the Chinese stone mill and mortar have been used for centuries and have cultural significance in various culinary traditions. They represent the ingenuity and resourcefulness of ancient civilizations in developing tools for food preparation and processing.

Chinese stone mill VS Quern-stone

Chinese Stone Mill:

The Chinese stone mill, also known as a quern mill or grinding mill, is a traditional tool used for grinding grains, seeds, and other materials. It consists of two large round stones, typically made of granite or basalt, with one stone placed on top of the other. The top stone is rotated manually or by an animal or machinery to grind the material placed between the stones. The grinding action is achieved through the friction and crushing of the grains between the stones, resulting in the desired texture or fineness of the ground product.

Quern-stone:

A quern-stone is a specific type of stone mill used for grinding grains and seeds. It is characterized by its flat, disc-like shape with a central hole. The quern-stone is usually made of hard stone such as granite or sandstone. The grinding process involves rubbing the grains or seeds against the flat surface of the quern-stone using a back-and-forth motion or by rotating a smaller handheld stone (known as a handstone) on the surface of the larger quern-stone.

The main difference between the Chinese stone mill and the quern-stone lies in their design and operation. While both tools are used for grinding grains, the Chinese stone mill typically consists of two vertically stacked stones, with one stone rotating over the other. In contrast, the quern-stone is a flat, horizontal stone with a central hole, and the grinding motion involves rubbing or rotating the grains against the flat surface. The quern-stone is often smaller and more portable compared to the Chinese stone mill.

Both the Chinese stone mill and the quern-stone have historical and cultural significance in different regions and time periods. They reflect the ancient methods of grain processing and the ingenuity of early civilizations in creating effective tools for food preparation.

stone mill story

During the reign of Emperor Taizong in the Tang Dynasty, there was a mill in the west of Chang’an City that housed a horse and a donkey. They were good friends, with the horse pulling loads outside while the donkey worked inside, grinding grain. In the third year of the Zhenguan era, the horse was chosen by the renowned monk Xuanzang to embark on a journey to India to retrieve Buddhist scriptures. After 17 years, the horse returned to Chang’an carrying the scriptures and was warmly welcomed by the people. The horse was granted an honorable title and became a celebrated hero among horses. It eagerly went back to the mill to meet its donkey friend.

The old horse shared its travel experiences with the donkey, describing the mythical realms it had encountered. The donkey was amazed and exclaimed, “You have witnessed so much! The distant paths you traveled are beyond my wildest imagination.” The old horse replied, “In reality, the distances we covered were roughly equal. While I journeyed to the Western Regions, you never stopped taking steps. The difference lies in the fact that I carried the great Master Xuanzang on my back and accomplished a valuable mission. Meanwhile, you were blinded and confined to revolving around the grinding mill, unable to break free from this narrow world and create significant value.”

Though we both sweat the same amount, the value produced often differs. This illustrates that the measure of achievement is not solely based on the amount of sweat shed but rather having a lofty goal that transforms small tasks into grand endeavors, generating substantial value.

dream stone mill meaning

- Dreaming of a stone mill, being in a low-key state within a crowd and enjoying focusing on one’s own things, often indicates that you haven’t found the right opportunity for yourself yet. As a result, you may choose to hide your strengths or quietly accumulate power, waiting for the right moment to unleash them.

- For businesspeople dreaming of a stone mill, it suggests a mixed outcome with both gains and losses. It is advisable to adopt a more defensive approach, especially if large investments are facing difficulties.

- According to the principles of the Five Elements in Chinese metaphysics, the auspicious color associated with dreaming of a stone mill is white. The wealth position is in the south direction, while the peach blossom position is in the southeast. The lucky number is 9, and garlic is considered a lucky food to enhance fortune.

- For individuals in their zodiac birth year dreaming of a stone mill, it is recommended to avoid unnecessary involvement, refrain from impulsive actions, and be cautious about potential reputational risks.

- For pregnant women dreaming of a stone mill, it indicates the birth of a baby boy, but the delivery may be delayed.

- For students dreaming of a stone mill, the autumn season is favorable, but academic achievements may not meet expectations, making it challenging to achieve desired goals.

- For individuals in a romantic relationship dreaming of a stone mill, it suggests that after going through multiple tests, marriage is likely to be possible.

- For people planning to travel who dream of a stone mill, it is advisable to postpone the trip or delay going out.

- If the dream involves a large stone mill, the travel plans should be delayed by one or two days.

- For individuals in a romantic relationship who dream of finding a small stone mill, it indicates a sincere and faithful attitude towards marriage, which is likely to succeed.

- Dreaming of someone else holding a stone mill signifies that individuals who usually pay little attention to small details or the emotional reactions of others should be more attentive and observant these days. Carelessness in dealing with people may lead to a significant reduction in how others perceive and evaluate you. It could also result in the rehashing of past failures or hinder progress in projects you are working on. Taking more time to understand the intentions of others will be beneficial.

- Dreaming of many stone mills for those in a romantic relationship suggests a love triangle, indicating the need to make a choice, which may lead to a successful marriage.

- For individuals in their zodiac birth year dreaming of a stone mill and soybean curd (tofu), it signifies a smooth and steady period. It’s time to let go of the past and take a step forward.

- For individuals in a romantic relationship dreaming of a broken stone mill, it indicates a minor dispute over a trivial matter that needs to be resolved through clear communication.

- Dreaming of someone else pushing a stone mill indicates that individuals who usually pay little attention to small matters or are not observant of others’ emotional reactions should be more attentive these days. Especially in dealing with others, a lack of care may lead to a significant discount in how others perceive you, and it may even bring up past failures to impede progress. It is essential to be more considerate and speculate on others’ intentions, as it will have positive effects on you.

- Dreaming of a stone millstone with the sun in your natal palace, combined with overall favorable luck, is an excellent opportunity to engage in activities you enjoy. If you want to express yourself or utilize your nurturing abilities, these are favorable days to do so. Visiting friends and engaging in conversations can also be a good idea, potentially resulting in unexpected gains.

- For individuals in their zodiac birth year dreaming of a stone mill and a grinding disc, it suggests that modesty and humility can bring good luck, and things are likely to go smoothly and according to your wishes.

- For pregnant women dreaming of a broken stone mill, it predicts the birth of a baby boy. However, in the spring season, the possibility of having a baby girl should be considered, and caution should be exercised to prevent accidents or injuries from heavy objects or stones.

- Dreaming of many old stone mills indicates that you, who can usually only focus on work or studies, can lead a busy life and feel excited. Try to approach everyone and everything with a sense of gratitude, not immersing yourself too much in the present. If you can maintain this attitude, the peace of mind experienced today will continue to exist in your future daily life.

Today, while modern technology has introduced more efficient milling methods, stone mills are still used in some traditional or artisanal settings, where their unique grinding mechanism is valued for producing high-quality products. They are also appreciated for their ability to retain the natural flavors and nutrients of the ingredients being milled.

Reference: Guizhou Political Consultative Conference Report “A Brief History of Stone Mills” by Wang Wujun, July 22, 2022.

Reference: “Suizhong Portal” article “Forgotten Time: Stone Mill” translated on October 13, 2019.

Reference: “The Symbolic Meaning of the Stone Mill: A Sacred Representation of Fertility Worship” by Jilin Daily, December 16, 2010.

Dear Yelang.

Very interesting article on Mo, I am from Mauritius and still have the Mo that my parents brought to Mauritius when they settled in the Island in 1940. We produced Tofu for more than 35 years and I did not have any idea about the Mo until I found your writings.

Thank you for sharing your experience and knowledge.